Automotive coating production line of the air shower used with ordinary place in the air shower overall structure principle of basic same, in addition to some details Settings, why do you say so, think about it actually very simple, also used in the coating line air shower for dust removal effect of some relatively higher requirements, after all, a car if there is a place no good spray paint, the loss is not just a typhoon shower price, here can also refer to the above why car painting workshop need air shower.

1, overview: air shower, clean workshop and fabricated clean room equipment, used to blow into the purification workshop of the human body and articles carried by the surface of air shower at the same time also have the effect of air brake, to prevent the air into the clean area without purification is for human purification equipment effectively and prevent the air pollution in a clean area.

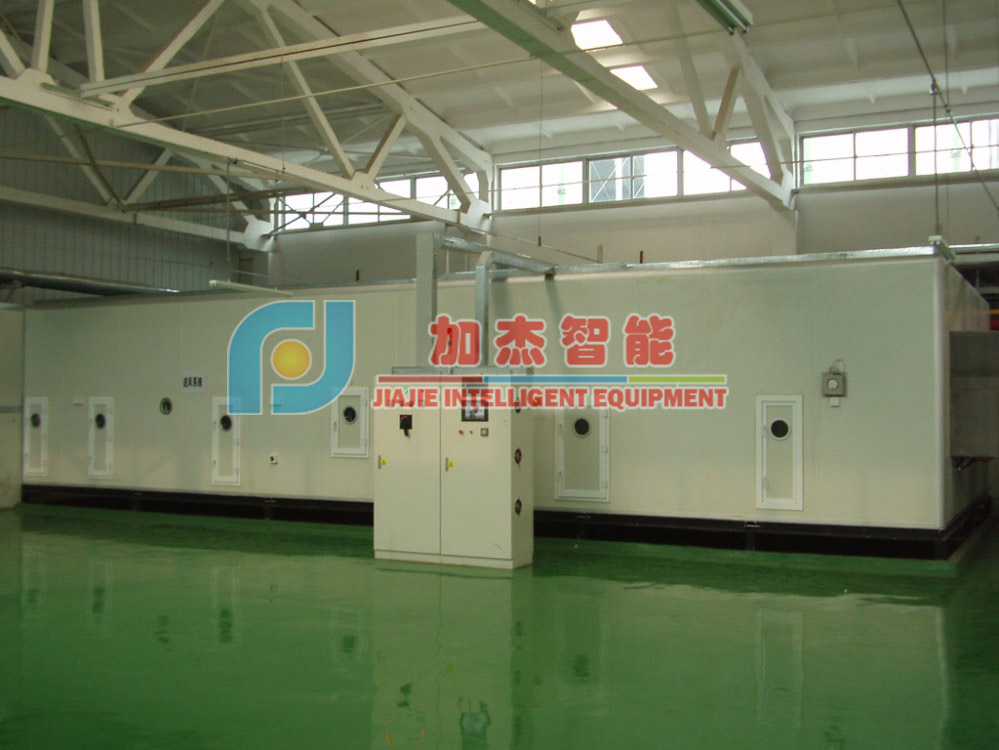

Structure: The series air shower rooms are equipped with foaming heat insulation color wall panels and aluminum alloy components, equipped with centrifuge fans and primary efficiency and high efficiency air filters, with beautiful appearance, compact structure, convenient maintenance, simple operation and other characteristics.

2, principle: air shower indoor air by the fan at the beginning of the effect of filter into static pressure tank, after the high efficiency air filter, clean air from the air shower of high-speed nozzle, the adjustable nozzle Angle, can effectively remove, or articles carried by the surface of blowing the dust under the recycle into effect at the beginning of air filter, so can achieve the purpose of the air shower.

3, use and characteristics: the air shower is a personal purification device used by operators when they enter the clean room. It USES high-speed clean air flow to spray away the dirt on the indoor personnel. Its nozzle can be adjusted to effectively remove the dust on the human body and prevent external pollution from entering the clean area. It can also be used in the shower of large goods.

4. Equipment composition: Mainly composed of room, lighting, filtration system, air unit, nozzle, electric control and other parts.

(1) Chamber body: The wall panel is made of color steel insulation board, and the inside and outside panels are all color steel plates. The center is filled with 60mm thick polystyrene, and PU foam is continuously formed. Inside and outside board and heat preservation material whole suppress and become an organic whole. The size of personnel entrance and exit gate is (width × height) mm: 700×1800.

(2) Indoor lighting: The lamp is installed on the top of the room. The lamp tube is made of philips high-efficiency light source, which is safe, energy-saving and easy to maintain. The ballast is made of special ballast for the spray room to ensure that the light intensity is ≥500Lx.

(3) Air supply and exhaust system:

A. The configuration scheme of air supply and exhaust adopts 1 set of air supply unit and 1 fan. The fan adopts centrifugal fan. A set of exhaust air unit is adopted to exhaust air from the chamber body.

B. Universal blowout nozzle: The universal blowout nozzle installed on the top and side of the chamber is used to blow the indoor air to different corners of the operator to ensure the clean quality.

C. Control system: Adopt imported or joint venture components to make the whole control system have higher reliability.

客户服务热线

客户服务热线