The car bumper is the car important exterior decoration part, along with the car coating request unceasing enhancement, the bumper coating also more and more receives each specialized factory's attention. Car bumper mainly adopts plastic material, coating on the surface is difficult to attach, and low thermal deformation temperature of the plastic parts, generally in use in the production of paint drying temperature is lower than the drying temperature of the coating used of the metal, so the plastic coating and metal coating are quite different in process and coating materials, bumper painting with car coating commonly mixed production line. At present, some large domestic automobile manufacturers have taken the injection molding and painting of the bumper as an important part of vehicle production, and built the injection molding and painting workshop of the bumper when planning the new factory. For example, Toyota has built a resin workshop (namely the injection molding and painting workshop of the bumper and other plastic parts) in the domestic construction factory. The bumper of some automobile factories in China is provided by the large-scale professional plastic parts processing factory, and the large-scale automobile plastic parts production factories in China include Jiangyin molding and Shanghai Yanfeng Weistong, etc.

The design of a number of bumper coating lines in China has absorbed the experience and technology of Japan, South Korea, Europe and The United States, etc. These coating lines have many different places in the process, equipment layout and mechanized form. In order to reduce the processing cost of plastic bumpers and improve their coating quality, a lot of researches have been made on coating materials, coating process and coating equipment, etc., and some achievements have been made. Therefore, the coating line design has undergone great changes in recent years.

1. Overall layout of coating line

The overall arrangement of large coating lines tends to be regionalized and three-dimensional. The same or similar equipment and processes should be arranged in the same area as far as possible to facilitate the organization and management of production. The first floor is mainly equipped with the upper and lower parts (including the cache area), pre-treatment, polishing, inspection, decoration and auxiliary equipment; The second floor is mainly equipped with spray paint room and air conditioning platform area; The drying room is arranged on three floors. This three-dimensional arrangement of equipment is more conducive to improve the cleanliness of the spraying clean area, which is of great help to improve the qualification rate of the products off the production line at one time. The whole painting workshop is a fully enclosed workshop, which is manually operated on one side of the production line during upper and lower parts. The high-end bumper painting adopts automatic spraying, and the exhaust gas in the painting room is discharged after centralized high-altitude emission or centralized incineration. The paint supply system adopts the combination mode of centralized paint supply and small line system paint supply.

2 Coating materials

Plastic bumper heat resistance is poor, when high temperature easy deformation, so the bumper coating generally cannot choose drying temperature is too high coating, drying temperature is about 80±5℃ and 120±5℃ for domestic paint. The bumper coating is composite coating namely primer + color paint + varnish, primer has two components and one component two, color paint mostly USES one component paint, varnish mostly USES two components paint. The two-component primer has a better covering force after baking, and can polish the surface particles and other paint defects, especially suitable for the appearance of the plastic parts are poor, but the two-component primer under the wet film state of electrical conductivity is generally poor, such as the primer is not dried spraying paint will affect the adhesion of color paint. Two - component varnish wide construction range, compared with one - component varnish, with less pollution, easy to adjust the advantages. The application of two-component primer and varnish system has disadvantages such as large equipment investment and complex maintenance of paint conveying pipeline, but the paint itself is easy to be adjusted, and it is easy to obtain a good surface condition of paint film.

3 Coating process

3.1 Main process forms of coating line

There are several commonly used coating processes for plastic bumpers:

Three spray and two drying (3C2B) process: top → pre-treatment → moisture drying → flame treatment → top masking → remove static electricity → primer spray → leveling → primer inspection/grinding → Remove static electricity → color paint spray → leveling → varnish spray → leveling → drying → strong cooling → inspection and modification → next parts → defective products repair;

Three spray and one drying (3C1B) top parts → pretreatment → moisture drying → flame treatment → top masking → remove static electricity → primer → leveling → paint spraying → leveling → varnish spraying → leveling → drying → strong cooling → inspection and modification → next parts → defective products repair;

The 3C1B process can save the one-time investment of equipment and the operating cost of equipment in the later stage. The existing plastic bumper coating line with large production capacity in China adopts this process form and has been put into mass production with relatively stable operation.

3.2 prior to processing

The pretreatment of the plastic bumper before painting is mainly to remove the dust, oil and residual release agent on the surface of the workpiece, and at the same time to activate the surface. Poor pretreatment can lead to poor adhesion, shrinkage cavity and particle defects. There are two forms of pretreatment, one is automatic spraying, the other is manual wiping. Automatic spraying is to hang the workpiece on the conveying equipment through the pretreatment spray line, the main process is: pre-degreasing → degreasing → washing 1→ washing 2→ fresh DI washing → water blowing → moisture drying → strong cold; Manual wipe is mainly used to wipe the whole workpiece surface manually with solvent, which can reduce the one-time investment of equipment and its operating cost. Domestic large quantities of plastic bumper coating line mostly adopts automatic spraying, small quantities of bumper coating and small parts coating mostly adopts manual wiping method.

3.3 Flame treatment

The flame treatment further activates the workpiece surface. The robot jets flames to the surface of the workpiece. Manual and automatic electrostatic removal procedures are set after the flame treatment process to enhance the binding force between the workpiece and the coating film.

3.4 on the cover

On the screen is mainly on the surface of the workpiece some do not need to be sprayed on the area to cover processing, the general line more difficult to cover, using more line shielding.

3.5 spray paint

Workpiece spraying mostly adopts the combination of robot automatic spraying and artificial spraying, first automatic spraying, and then manual inspection of supplementary spraying. Some production lines can be completely automatic spraying after commissioning and enter into mass production. Automatic painting mainly adopts robot spraying. Generally, air spray gun is used for primer, cup rotary workstation + spray gun workstation is used for color paint and spray gun + cup workstation is used for varnish 2 workstations.

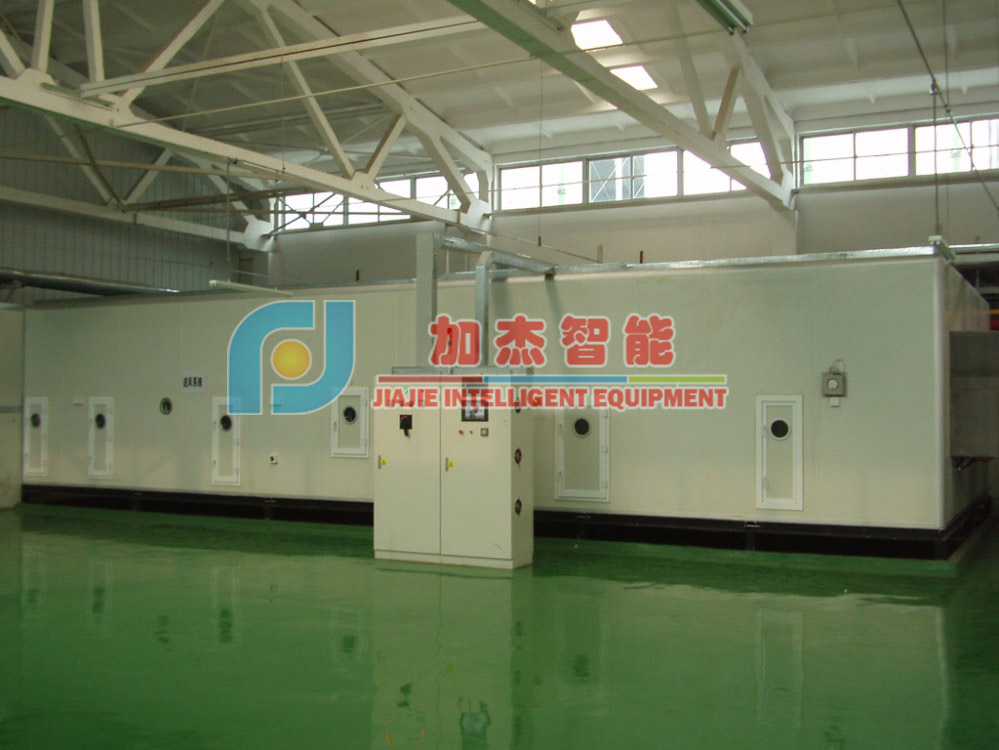

4 Coating equipment

The equipment of plastic bumper coating line mainly includes mechanical conveying equipment, pretreatment equipment, flame treatment equipment, spray painting room equipment, drying furnace and artificial working area equipment, etc.

4.1 Mechanical conveying equipment

Plastic bumper spraying line mechanized transport equipment in the form of more, there are general suspension transport chain, reverse cumulative chain and skid transport, friction transport form. Skid transport layout is flexible. In recent years, many production lines built in China have adopted skid transport. Japanese bumper coating line mainly adopts reverse cumulative chain and friction transport mode. Considering that some equipment of the pretreatment process conveying system has the requirements of waterproofing and anti-rot and the influence of drying process temperature, the driving device of the skid conveyor system in the general pretreatment and drying process adopts the external type.

4.2 Pre-processing equipment

The pretreatment equipment mainly includes non-standard equipment, circulation system and exhaust system. The degreasing liquid of plastic bumper is slightly acidic (pH value is generally around 6.4), which is different from the degreasing liquid of car body, so the pre-treatment equipment should consider acid resistance, it is recommended that the pre-treatment closed chamber body and tank body adopt stainless steel material. The top of the pre-treatment equipment room is equipped with an exhaust fan to avoid the gas diffusion to the outside of the room. It is suggested that a maintenance platform, a maintenance door and a cantilever searchlight be installed on one side of the pre-treatment room to facilitate the maintenance and repair of the equipment.

4.3 spray room

The existing domestic painting production line of the spray painting room has The Van Winkle spray painting room, the water spin spray painting room and the water curtain type spray painting room and so on, now USES the Van Winkle spray painting room. There are two kinds of air supply and exhaust system in spray chamber: fresh air and self-circulation air. The all-fresh air mode is that the air supply air conditioning unit in the spray chamber takes air from the outside of the chamber and sends it to the spray chamber after multi-stage treatment of the air conditioning unit. After the air is utilized in the spray chamber, the exhaust fan in the spray chamber is all discharged into the atmosphere. The self-circulation air mode is the air circulation utilization in the spray painting room (that is, the air enters the spray painting room through the air supply air conditioner, and then returns to the air supply air conditioner through the circulating air treatment equipment for reuse), the air in the spray painting room is not all discharged, only part of the discharge and part of the supplement. The amount of air supply and exhaust shall be calculated according to the balance of air flow in the spray chamber, the limit concentration of exhaust gas explosion in the spray chamber and the requirements of paint performance. Some production lines are designed to supplement the air flow with 10%, 30% of the total circulation air flow. The air volume of spray chamber exhaust and fill air should not be too low, too low will lead to the circulation of the wind organic solvent content is too high, easy to cause paint film surface gloss, and spray construction parameters control is more difficult. The concentration of exhaust gas in the spray chamber with circulating air is high (exceeding the requirements of national environmental protection standards), and the exhaust gas shall be incinerated back into the atmosphere (the exhaust gas after incineration can meet the national environmental protection requirements). The temperature of the painting room is generally required to be controlled at about 23℃, heat exchange in winter, refrigeration in summer, the use of fresh air coating production line energy consumption is large. The use of circulating air conditioning can reduce the energy consumption of production line (comprehensive energy consumption can be reduced by more than 30%, the installed power of related equipment can be reduced by 40%), and save the operating cost. Spray chamber adopts circulation air supply, corresponding spraying form should adopt automatic spraying, because the circulation air harmful gas content is high, not suitable for manual operation, such as artificial spraying should wear clothing and masks with anti-gas function.

4.4 drying furnace

Baking furnace are mainly in the form of straight through, bridge and П type 3 kinds. The mechanical conveying of Japanese coating production line mostly adopts the form of reverse cumulative chain, and the drying furnace is the bridge drying furnace. Europe and the United States system using light skid transportation system, drying furnace for drying furnace П type. Double stroke drying oven is used to reduce heat dissipation area and energy consumption.

4.5 Paint supply system

There are two paint systems, one is the centralized paint system, that is, all the paint is concentrated in a specific area for deployment, the centralized paint system to be arranged in the distance of three paint rooms near the place, to reduce the paint pipe passing long caused by the pressure loss and temperature loss, and avoid the pipeline cleaning difficulties; The other is the line edge system, that is, the paint transfer equipment is placed near the spray chamber. The volume of paint supplying tank used by the line-edge system is relatively concentrated, so the line-edge system is also known as the small system. The advantage of the small system is that it can meet the spraying production under the condition of small paint feeding. It can be used for infrequent production of color paint, new color trial production and temporary adjustment of color coating. A centralized paint system is used for primers, varnishes, and several high volume paints.

客户服务热线

客户服务热线